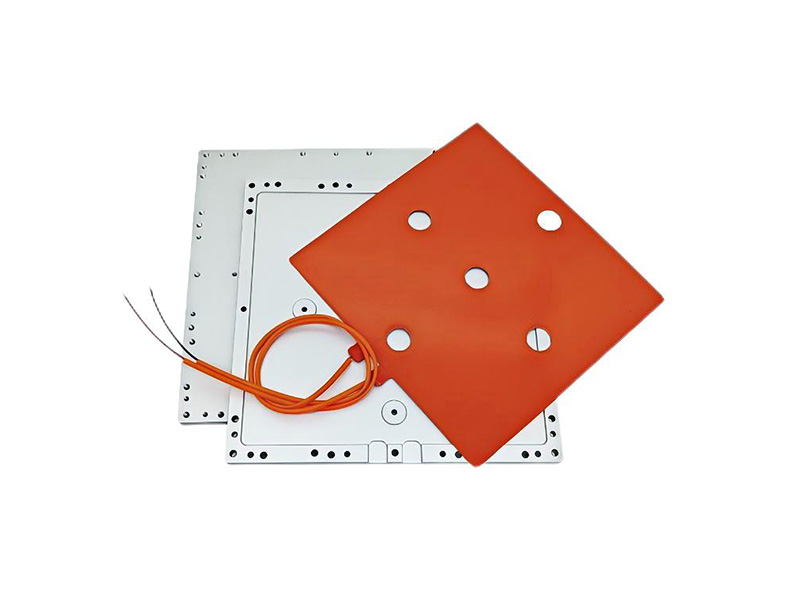

Aluminum heating plates are essential components in industrial dryers, providing fast and even heat distribution to remove moisture from materials efficiently. These plates are built with embedded silicone heaters, combining the durability of aluminum with the flexibility and precision of silicone heating technology.

What Makes Aluminum Heating Plates Special?

Industrial drying demands both speed and consistency - aluminum heating plates deliver this through superior thermal engineering. By combining high-performance materials with smart design, they solve key production challenges:

1. Fast & Even Heating: The embedded silicone heaters ensure rapid and uniform heat distribution across the plate surface.

2. Durable & Lightweight: Aluminum construction offers excellent heat conductivity and long-lasting performance.

3. Customizable: Available in various sizes and power ratings to meet specific drying requirements.

4. Easy Integration: Designed for seamless installation in industrial dryers, reducing downtime and maintenance.

How Aluminum Heating Plates Solve Real-World Problems?

A leading snack manufacturer struggled with uneven drying in their 2-meter conveyor dryers - resulting in 15% product waste from inconsistent moisture levels. Their existing steel heating plates created hot spots while consuming excessive energy.

We engineered custom 2.2-meter aluminum heating plates with embedded 5kW silicone heaters, specifically designed for their production line. The advanced thermal design achieved remarkable ±2°C temperature uniformity across the entire drying surface - eliminating hot spots completely. This innovation slashed system warm-up time by 38% (from 45 down to 28 minutes) while paradoxically enabling 20% faster conveyor speeds, all without compromising product quality. The aluminum's superior heat conductivity allowed faster heat transfer while using less energy compared to their old steel plates.

Why Aluminum Heating Plates Transform Industrial Drying?

In industrial drying operations, uneven heat distribution leads to wasted energy and inconsistent product quality. Aluminum heating plates solve these challenges through their superior thermal conductivity, delivering ±2°C temperature uniformity across the entire drying surface. This precise heating eliminates hot spots while reducing energy consumption by 15% compared to traditional steel plates.

The combination of fast heat transfer and customizable sizing makes them ideal for demanding production environments. For food processors and manufacturers, this technology translates to faster cycle times, higher product consistency, and significant cost savings - proving that superior thermal engineering drives operational excellence.

Optimiser le séchage industriel avec des plaques chauffantes en aluminium avancées

Ces solutions de chauffage avancées offrent un transfert de chaleur précis et uniforme qui élimine les incohérences de séchage dans les applications alimentaires, textiles et pharmaceutiques. En combinant l’efficacité thermique de l’aluminium avec les appareils de chauffage en silicone intégrés, ils surpassent les options conventionnelles en termes de performance et de fiabilité.

Leur conception adaptable s’intègre parfaitement aux lignes de production, garantissant des résultats cohérents tout en réduisant les coûts opérationnels. Pour les fabricants qui privilégient la qualité et l’efficacité, les plaques chauffantes en aluminium offrent une mise à niveau éprouvée qui améliore l’ensemble du processus de séchage.

Nous offrons une grande variété de chauffage à haut rendement et d’éléments chauffants. Tels que les appareils de chauffage polyimide/kapton, les appareils de chauffage en caoutchouc silicone, les appareils de chauffage transparents PET, les appareils de chauffage à film épais, les appareils de chauffage PTC, les appareils de chauffage à mica, les appareils de chauffage à résine époxy et les films de chauffage au graphène.